Our Mission

It's quite simple really, to design and build products that we want to use over anything else that's out there.

MADE IN CANADA

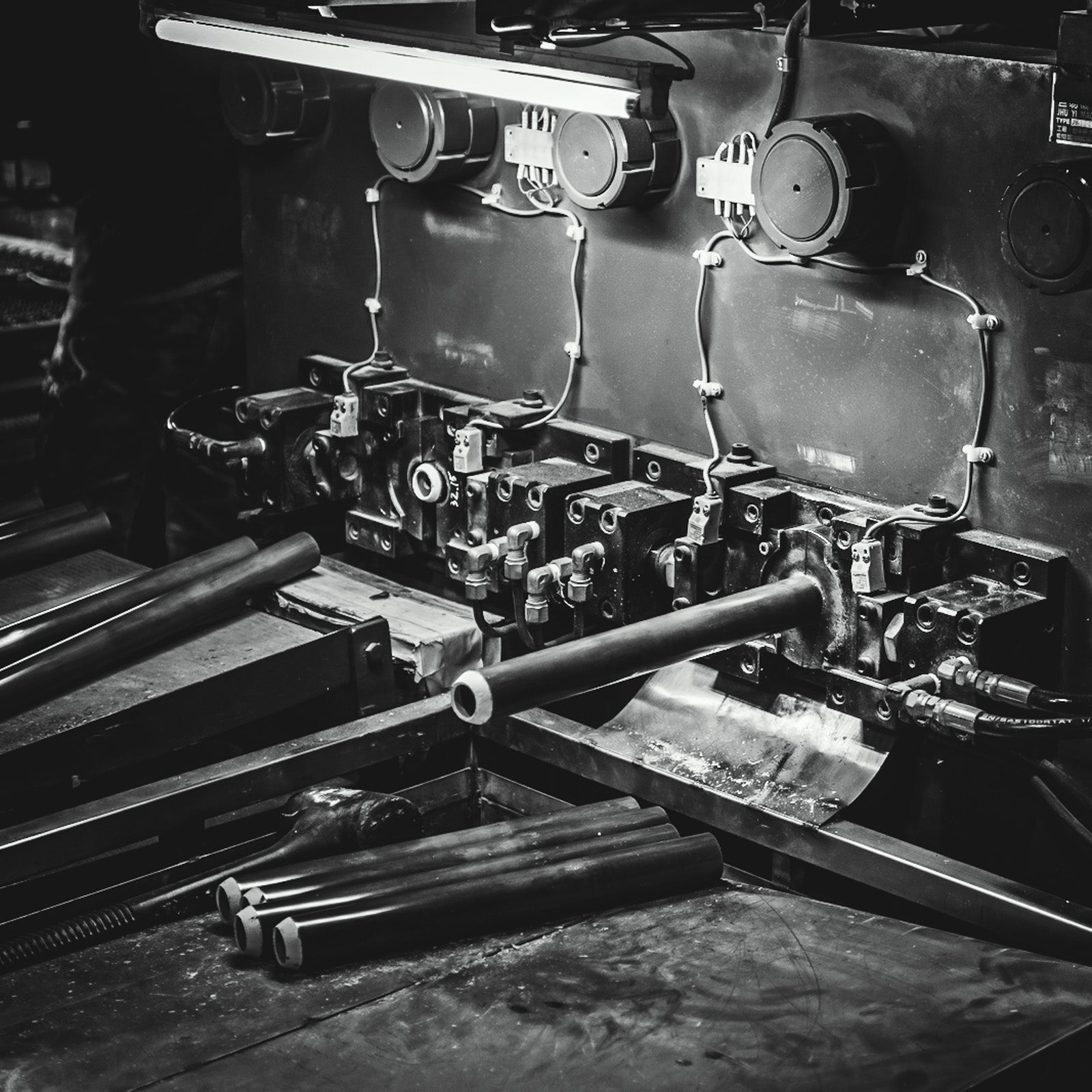

Not all of our products are manufactured in Canada but we still make a wide variety of our line right here in beautiful British Columbia.

Anything from QR's and stems, to frame parts such as cable guides and bottom brackets are CNC machined next door at North Shore Billet. Not only does it support the Whistler economy and put money into the hands of avid mountain bikers, it also gives us unparalleled access to product development and quality control.

Made in Taiwan

We've never tried to hide the fact some of our products are made in Taiwan, in fact, we're proud of it.

Our Taiwanese partners are incredibly skilled and some of the best in the business. As such these products are held to the same strict standards that we're renowned for.

The Arcturian and Samurai are hand welded by Mike Truelove in Squamish. Mike also does a great deal of our prototyping.

The Surface and most Primers are made by Chris Dekerf in Vancouver. Chris also does all of our custom paint jobs.

Our latest welder Brad Howlett is making the Doctahawk on Vancouver Island.

We also use local print and embroidery where possible for small runs of clothing.

MIKE TRUELOVE - BIKE WELDER

REPAIR

We know that cycling takes it's toll on your gear. That's why we repair clothing to keep it out of the landfill for as long as possible.

We encourage you to swing by or contact us if you have questions about repairing your Chromag clothing.

MERINO WOOL

Wool is a great natural alternative to plastic synthetic fibres. It is low in energy and water consumption and exhibits extremely high performing properties. Merino wool fibres absorb and pull moisture vapour away from your body unlike synthetics which can only wick away the moisture once it has condensed. One square inch of skin on a merino sheep produces about 4 times as many wool fibres as other breeds of sheep.

Merino wool has paradoxical properties making it ideal for use year round. In the summer it is ideal for wicking moisture away from your body. In the winter, the natural structure of the fibre inherently blocks larger drops of water while continuing to wick away vapour. When vapour is absorbed into wool it binds to the chemical structure of the fibres and small amounts of energy are released in the form of heat. This principle is known as the "heat of sorption".

We also use local print and embroidery where possible for small runs of clothing.

The crimped structure of wool fibres creates fabrics loaded with tiny air spaces which act as nature’s most efficient insulator adding to wool’s reputation for warmth and comfort. It is the air trapped between the wool fibres and not the fibres themselves that keep you warm. Because Merino wool fibres are smaller in diameter and they are more numerous than coarser wools, they trap more air pockets and keep you warmer.

All of our merino wool products use ethically sourced wool from New Zealand farms. This means the animals are treated fairly, they don't practise mulesing or tail docking. These farms also practise sustainable land management.

Packaging

We know we're not perfect, but we are constantly striving to improve. We use recycled cardboard for our hangtags, and we're striving to cut down our plastic packaging, for example on the Roam, Veldt and Recluse jerseys in our merino wool line.

We're constantly reducing single-use plastics in our packaging. Even if it's just a sticker, or a nylon clothing tag. For example in our sock packaging we've removed the little plastic hooks and barbs, and in our gloves we replaced the elastic and metal clasps with paper string. It doesn't seem like a lot, but over thousands of pairs of socks it has an impact. It keeps these components, that are often overlooked when the end user comes to recycling, from the landfill or ocean.

We've moved our chainring packaging to 100% cardboard, with no plastic stickers for the closure, meaning it can go straight back to being recycled without a need for the end user to strip any plastic parts or labels.

RECYCLING & COMPOST

We practice both recycling and composting diligently here at Chromag in an effort to reduce our footprint on the planet.

Whether it's generated by the staff or by the business, we are strict about making sure as little as possible ends up in the bin. We have a designated frankenbike with a trailer that we use to take out the recycling.

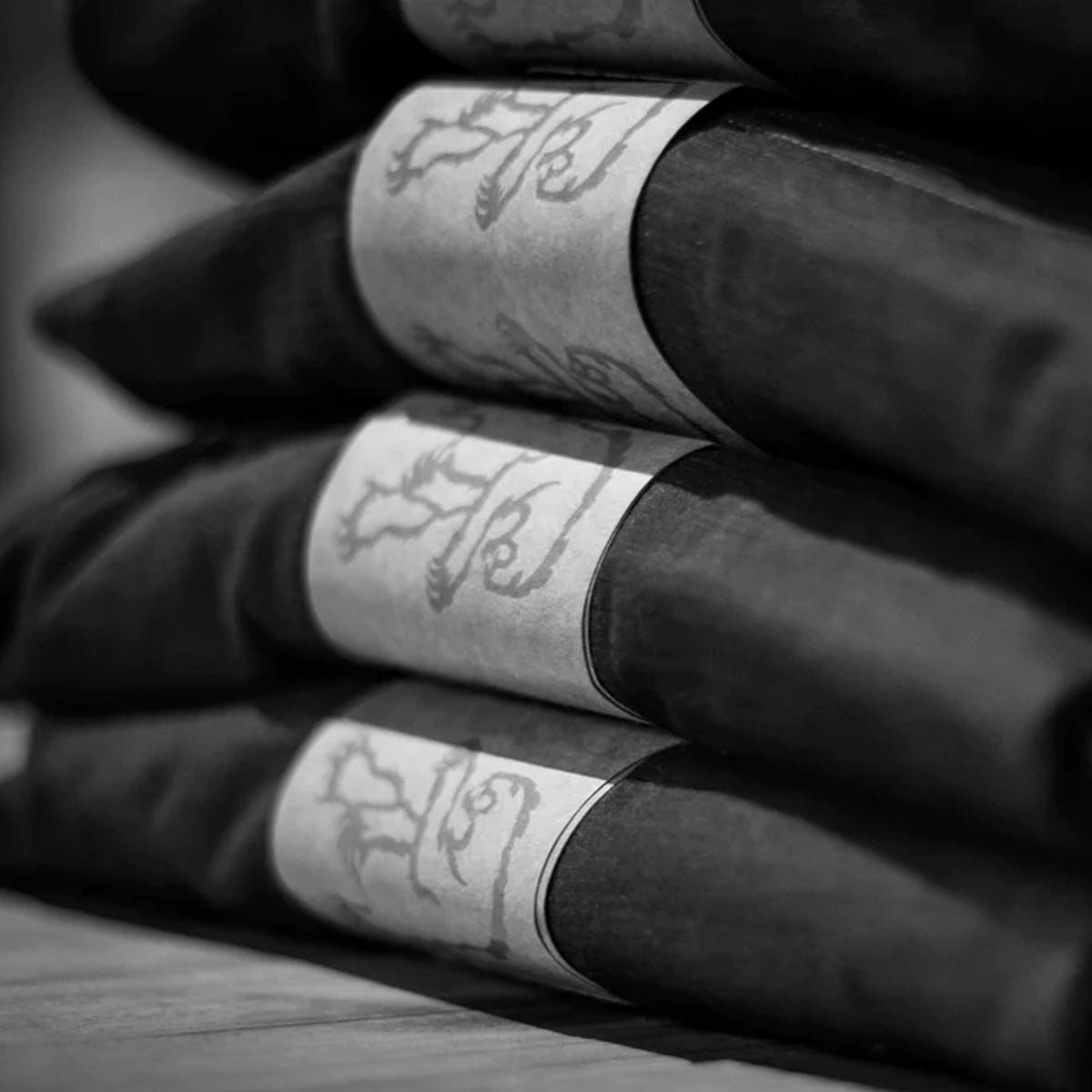

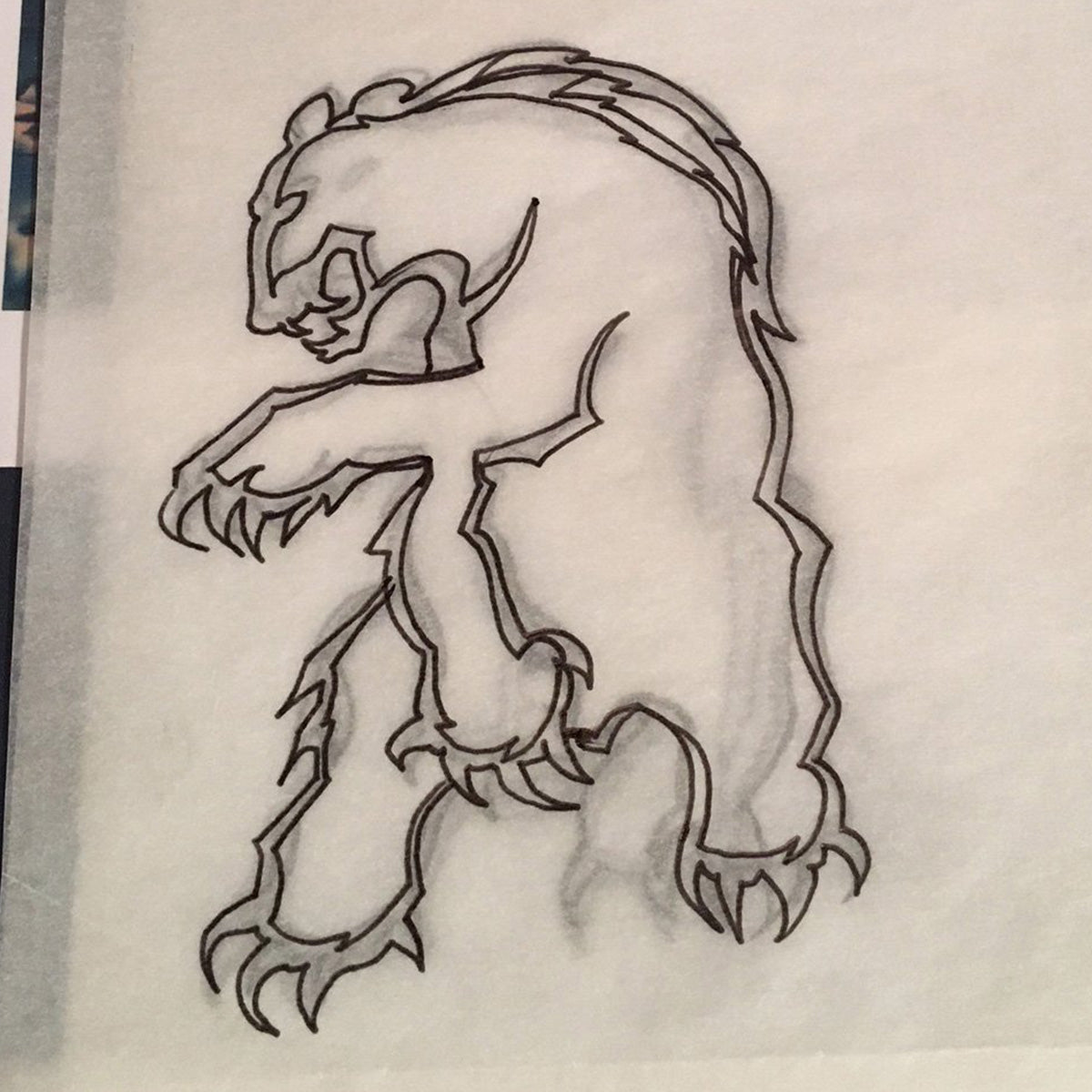

The Bear

The actual origin of the logo comes from a tiger that Ian drew when he was a kid. The tiger was standing on top of a mountain and swiping at planes flying by.

When Ian started Chromag in 2003, he asked his mum to draw a bear and base it off the tiger. This is what she came up with.

Since then it's been sharpened and cleaned up a bit, but the same original design is still very much apparent. We have also developed two typefaces called Chromagnum and Chromagnum Black which form the "Race" logotype you will probably be most familiar with today.

THE CHROMAG CREW

A great proportion of the staff make an effort to ride to work every day. A select few even when there's snow on the ground (bar mitts are a wonderful thing!).

Throughout the summer (or any time there's not snow on the ground) the whole crew generally ride together twice a week. Once after work on Tuesdays (commonly referred to as One Bottle Rides) and again on Fridays, usually for a bigger mission. Feel free to pop by and find out where we're headed.

We have staff yoga once a week here at HQ and a daily "scurv plate" of fruit to keep the staff fighting fit. A lot of us also go to spin classes several times a week throughout the winter to stay in shape, not to mention all the staff are avid skiers and snowboarders. Except for Matty Richard, he can't ski for sh*t.